|

Both systems utilzes the Coanda effect, the main difference between NOTAR and CoCoMo systems is in the energy efficiency of the downward flow of the air.

The enclosed variable-pitch blade fan delivers slightly pressurised air into the tailboom. The air goes through patented turbulization system which increases energy of Coanda flow and after that is expelled through two slots which run the length of the tailboom on the starboard (right) side, causing a boundary-layer control called the "Coanda Effect". The result is that the tailboom becomes a "wing", flying in the downwash of the rotor system, producing balancing anti-torque force.

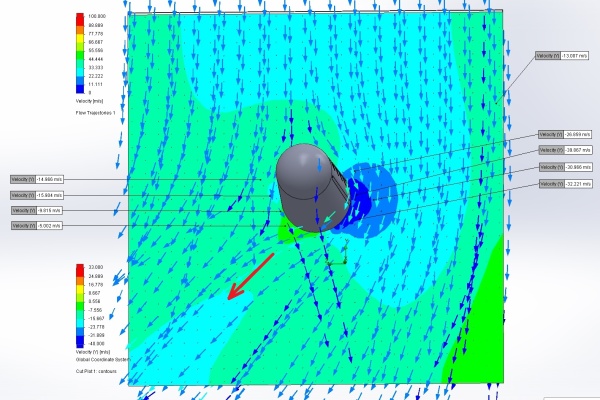

This picture illustrates unbalancing of velocity matrix on the left and right side of helicopter tail boom equipped with CoCoMo.

The average velocity is 13 m/s, values on the left side aprox. 5 - 6 m/s, on the right side 27 - 40 m/s. Such operational regime can be considered as a “normal” one for CoCoMo, but this mode is a maximal one for the NOTAR.

Part of the CoCoMo system which utilizes the Coanda effect is much more efficient because CoComo can deflect downward airflow more than 90 degrees from the vertical direction. NOTAR downward airflow can not deflect more than 30 or max.40 degrees.

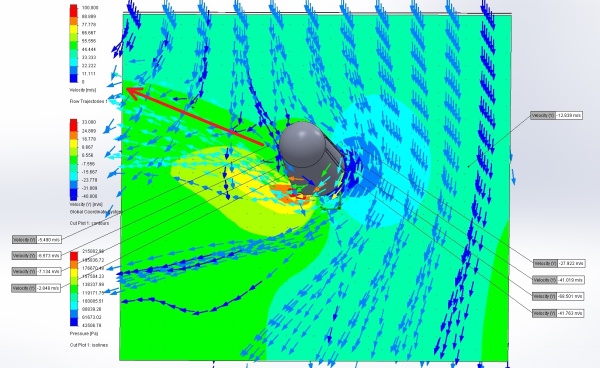

Maximum achievable deflection of downwash air vector for the CoCoMo system:

Values V(y) are on the left side are in the range between 2 - 7 m/s, on the right side 27 - 69 m/s. The velocity of the main matrix is still around 13 m/s. Color coded heat map shows very significant pressure difference between left and right side. Velocity vectors in the area up to 15 cm from the tail boom surface are deflected up to 130 degrees against original vertical downwash flow vector.

CoCoMo is so efficient that it does not to employ any direct jet thruster for directional control - directional control is fully provided by CoCoMo regulation.

You can see CoCoMo animated simulation:

|